Pipes, Trunks & Accessories

High Quality Plastic Pipes & Accessories

Plastic pipes find extensive use in plumbing, irrigation, drainage, and HVAC (heating, ventilation, and air conditioning) systems in residential, commercial, and industrial settings. They are lightweight, easy to install, and resistant to corrosion, chemicals, and rust, making them ideal for both above-ground and underground applications. Plastic pipes are also preferred for their smooth interior surface, which promotes efficient fluid flow and reduces the risk of clogs and blockages.

High Quality Plastic Pipes

The best plastic pipes for

your projects

Plastic pipes are versatile and widely used in various industries and applications for their durability, flexibility, and cost-effectiveness. These pipes are made from different types of thermoplastic materials, such as PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), PE (polyethylene), PP (polypropylene), and PEX (cross-linked polyethylene), each offering unique properties suited for specific uses.

Overall, plastic pipes offer a reliable and cost-effective solution for a wide range of plumbing, electrical and piping applications. By selecting pipes with the appropriate specifications for the intended use and ensuring proper installation and maintenance, users can benefit from long-lasting performance, reduced maintenance costs, and enhanced efficiency in their plumbing and piping systems.

Specification

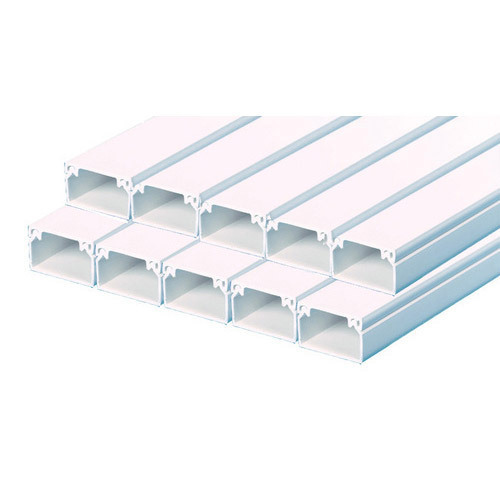

High Quality Plastic Trunks

Reliable plastic trunks for your needs

Plastic trunks, also known as cable trunking or wire ducts, are protective enclosures designed to organize and conceal electrical cables, wires, and conduits in various applications. Made from high-quality thermoplastic materials such as PVC (polyvinyl chloride), ABS (acrylonitrile butadiene styrene), or halogen-free materials, plastic trunks offer a durable and cost-effective solution for cable management needs in residential, commercial, and industrial settings.

These trunks serve several purposes, including organizing cables to prevent tangling and tripping hazards, protecting cables from physical damage, and enhancing the aesthetics of interior spaces by concealing unsightly wires. They are commonly used in office buildings, data centers, factories, schools, hospitals, and residential homes to route and protect electrical, data, and communication cables.

Specification

Hight Quality Corrugated Pipes

Flexible robust corrugated pipes

exceeding your requirements

Corrugated pipes are flexible tubes with a corrugated exterior and a smooth interior surface, typically made from high-density polyethylene (HDPE) or polypropylene (PP) materials. These pipes are commonly used in a wide range of applications for their versatility, durability, and ease of installation.

Corrugated pipes are also used in various other applications, including agricultural drainage, culvert and bridge construction, septic systems, and underground utilities such as electrical and telecommunications conduits. They can be installed horizontally, vertically, or in a trench, depending on the specific requirements of the project.

Specification

High Quality Accessories

High Quality Boxes & Fittings for your installations

Plastic fittings and boxes are essential components in electrical and plumbing systems, offering versatility, durability, and ease of installation. These fittings and boxes are typically made from high-quality thermoplastic materials such as PVC (polyvinyl chloride) or ABS (acrylonitrile butadiene styrene), known for their resistance to corrosion, chemicals, and impact.

In electrical systems, plastic fittings and boxes are used to connect and protect electrical wires, cables, and devices, ensuring safe and reliable operation. Electrical fittings such as conduits, couplings, elbows, and junction boxes facilitate the routing, branching, and termination of electrical wiring, while providing mechanical protection and insulation. Plastic electrical boxes, available in various sizes and configurations, serve as enclosures for switches, outlets, and electrical connections, protecting them from damage and facilitating their installation in walls, ceilings, or floors.

Specification

High quality manholes

Heavy duty Manholes for your projects

Plastic manholes, also known as inspection chambers or access chambers, are essential components in sewage, drainage, and utility infrastructure systems. These manholes are constructed from high-density polyethylene (HDPE) or polypropylene (PP) materials, offering durability, corrosion resistance, and ease of installation.

Plastic manholes serve as access points to underground pipelines, allowing for inspection, maintenance, and repair of sewer lines, electrical cables, stormwater drainage systems, and utility conduits. They provide a secure and watertight enclosure for accessing valves, junctions, and connections within the network, while also preventing ingress of debris, groundwater, and unauthorized access.

Specification

Key Qualities

03.

Lightweight

Plastic pipes and fittings are significantly lighter than their metal counterparts, making them easier to transport, handle, and install.

01.

Durability

Plastic pipes and fittings are highly durable, capable of withstanding a wide range of environmental conditions, including moisture, chemicals, and temperature fluctuations.

04.

Flexibility

Flexible enough to facilitate easy installation and routing through walls, ceilings, and conduits. This flexibility is advantageous in applications where pipes need to navigate around obstacles or follow irregular paths.

02.

Corrosion Resistance

Unlike metal pipes and fittings, plastic materials such as PVC, CPVC, and PEX are inherently resistant to corrosion, rust, and chemical degradation which is needed in your projects.

05.

Ease of Installation

Plastic pipes and fittings are typically joined using solvent cement, compression fittings, or heat fusion methods, which are simple & straightforward compared to welding or soldering.

Key Qualities

01.

Durability

Plastic pipes and fittings are highly durable, capable of withstanding a wide range of environmental conditions, including moisture, chemicals, and temperature fluctuations.

02.

Corrosion Resistance

Unlike metal pipes and fittings, plastic materials such as PVC, CPVC, and PEX are inherently resistant to corrosion, rust, and chemical degradation which is needed in your projects.

03.

Lightweight

Plastic pipes and fittings are significantly lighter than their metal counterparts, making them easier to transport, handle, and install.

04.

Flexibility

Flexible enough to facilitate easy installation and routing through walls, ceilings, and conduits. This flexibility is advantageous in applications where pipes need to navigate around obstacles or follow irregular paths.

05.

Ease of Installation

Plastic pipes and fittings are typically joined using solvent cement, compression fittings, or heat fusion methods, which are simple & straightforward compared to welding or soldering.